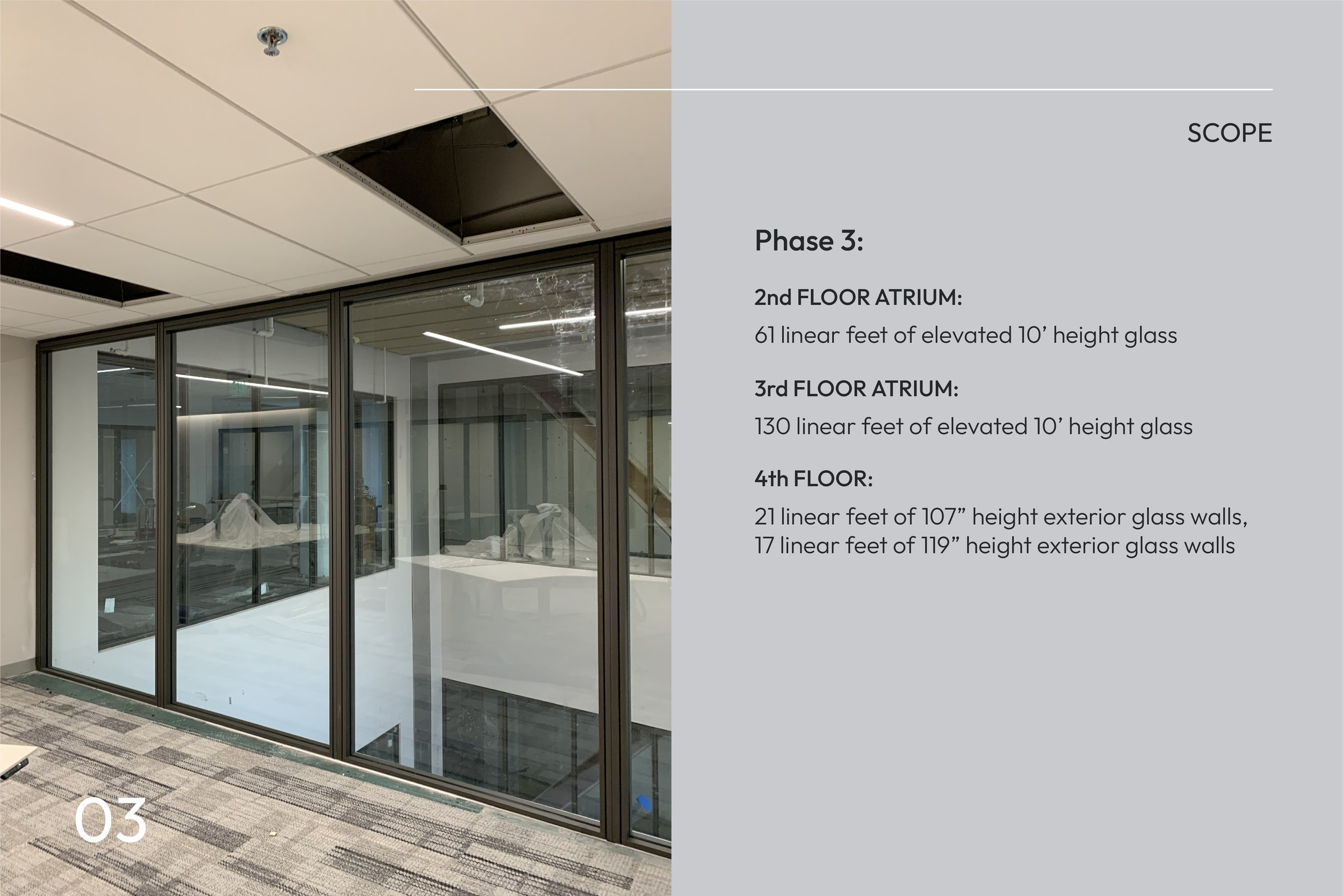

A Vast Glass Wall Install for a Biotech Headquarters

Our wall-installation work for the HQ of a major biotech company exemplifies the depth of capacity we bring to large, complex projects.

To realize the glass-heavy design vision for this South San Francisco hub, we assembled 4,000 linear feet of glass walls.

Our installation work included glass interior and exterior walls, railing glass, and, the crowning achievement, ten-foot-high glass walls lining a three-story atrium.

CHALLENGES AND HOW WE OVERCAME THEM

The building’s open core provided some unique challenges to installation. To achieve the end goal, we brought in our most skilled teams, planned out every step, and developed creative solutions, such as using scissor lifts to navigate the space.

Given the heightened risks of this kind of installation, we also implemented rigorous safety precautions. This project ranks high for difficulty, risk, and scale, but we’re proud to say that with the coordinated efforts and precision work of our high-caliber crew, we more than rose to the occasion. Please read on for details!

Going the distance to plan for safety

Preparation was crucial to the execution of such a complex project. Working literally on the edge of a multistory drop, we had to implement safety measures to prevent any falls. So we mapped out how harnesses and safety straps would be secured.

Not only did we ensure compliance with Cal/OSHA (California Occupational Safety and Health) guidelines for contractors, we stationed a safety officer on site 24/7 to support our team. These measures kept every crew member safe so they could complete the job on time and to the highest quality.

Reaching new heights: product delivery without an elevator

An early challenge of the project involved transporting the product to the building’s upper floors. Because the wall units were too large for the elevators, we had to resort to more challenging methods of transport: carrying the materials by way of these glassed-in stairs, pictured here, or by scissor lift.

Thanks to our team’s strength and agility, step by step, scissor lift by scissor lift, our solution worked. All materials arrived safe and sound to the designated areas for distribution and placement.

A frame job to brag about: scissor-lift assisted trim installation

With materials distributed, we moved onto the precision work of trim cutting and installation. Given the project’s three floors of framed glass, we had plenty of trim that needed to be cut and fitted exactly.

To actually install the trim—and later the wall units themselves—we tackled the challenge of negotiating the open atrium space. Usually, for wall installation, you’d have a crew on either side of floor-to-ceiling panels, with solid ground underfoot. As we had solid ground on only one side, we used scissor lifts as platforms for our installers working on the open-atrium side. We needed our best crew to perform this detailed, high-risk work, and they delivered.

Ten-foot-tall walls, sprinkler systems, and other obstacles we overcame

When it came to the actual installation of the ten-foot glass walls, the process demanded coordinated effort, precision—and safety measures.

We’ve removed floor tiles so that the safety straps are secured to the concrete, ensuring that the crew is firmly anchored in.

At this stage of the process, we faced another difficulty: maneuvering the walls around the sprinkler system. In the photo below, you can see the teamwork required to steer these heavy glass panels. Once clear of the sprinkler heads, the crew then had to push the walls up and into place on the track.

We’re proud to report that no sprinklers—or humans—were harmed in the making of these walls.

A luminous finale lets the sun shine through

The completed installation transforms the building into a radiant light-filled structure. Perfectly installed, the floor-to-ceiling glass pulls maximum light into these office interiors. From planning stages through every phase of the installation, we brought attention to detail together with high-quality teamwork to fulfill the project's vision.

By deploying our best crew, we had all of the strength, agility, and top-level installation skills needed to take on the complexities of the job. And all along the way of this physically-demanding operation—handling hundreds of feet of glass over an open atrium—we kept our team safe and our standards high.